ARC Vanture JV – Technical Data Sheet

Equipment: Water Evaporator Units (ZT-Series)

Supplier: ARC Vanture Joint Venture

1. General Description

ARC Vanture’s Water Evaporator Units are engineered for large-scale dewatering and water management in mining, industrial, and environmental applications. These units offer a rapid, cost-effective solution to excess water, with modular deployment, full automation, and remote monitoring. Systems can be supplied as single units or scaled into multiple-unit operations for high-volume evaporation requirements.

2. Equipment operating principles

Water Evaporators operate on the principles of liquid atomisation and air jet technology. First, a high-pressure pump pressurises the liquid, which is then atomised through a special nozzle. A powerful high-pressure fan then propels the fine water mist over long distances. Thanks to its large air volume and strong airflow, the mist can reaches distant areas and covers large surfaces.

As the mist spreads, dust particles in the air come into full contact with the water droplets and become moistened. These damp particles begin to attract and bind with other dust particles, forming larger clusters. Once heavy enough, these clusters fall under their own weight. This process effectively suppresses and reduces dust, helping purify the air and improve overall air quality.

Advantages

- Long spray range, strong penetration, wide coverage, fine and evenly distributed mist. It delivers rapid dust reduction and high operational efficiency.

- Equipped with an intelligent PLC control system for precise, timed, and directional operation.

- Flexible power options: can run on municipal electricity or via an external generator.

- Highly mobile: can be mounted on vehicles, towed, or installed on platforms or towers.

- Multiple safe and reliable operation modes: can be controlled manually or via remote control up to 100 meters away.

- High efficiency, energy-saving, water-saving, and low noise. Compared with traditional spray guns or sprinkler trucks, it reduces water consumption by 70–80% while covering a much larger area.

A high-pressure pump pressurises the liquid, which is then atomised through an atomising nozzle. Subsequently, a high-pressure jet fan, with its large air volume and high air pressure, propels the atomised water mist to a relatively long distance, allowing the mist to reach faraway areas and cover a larger surface.

During this process, dust particles come into full contact with the water mist particles and become moistened. These moistened dust particles then adsorb other dust particles, condensing into larger particle clusters. Under the influence of their own gravity, these clusters settle down. This process achieves effects such as dust suppression and reduction, thereby purifying the air and improving air quality.

3. Advantage

– Long range, strong penetration, wide coverage, small water mist particles, and uniform spraying; it features fast dust reduction speed and high work efficiency.

– The intelligent PLC control cabinet enables quantitative, timed, and directional operation.

– Flexible power matching: it can use either municipal grid electricity or be driven by a supporting generator set.

– Flexible mobility: it can be equipped on a vehicle, moved by ground traction, or installed on various platforms or towers.

– Multiple operation methods, safe and reliable: it can be operated manually or via precise remote control within a distance of 100 meters.

– High efficiency, energy saving, water saving, and low noise: compared with other dust suppression spraying equipment (such as spray guns and sprinkler trucks), its water consumption can be reduced by 70%-80%, and the water mist coverage area is much greater than that of other spraying equipment.

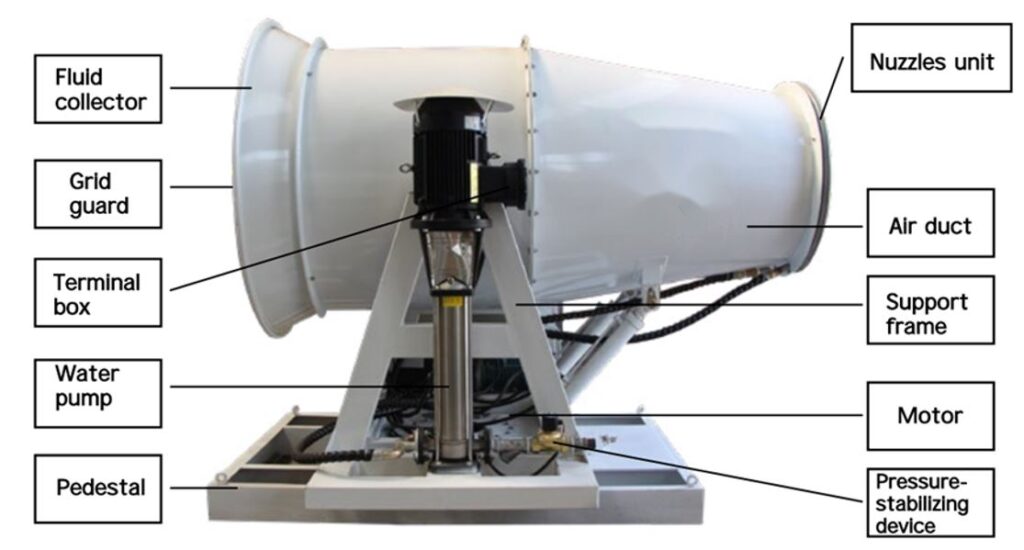

4. Structure

5. Applications & Function

| Parameter | Description |

|---|---|

| Applications | Mine site dewatering, rainfall/run-off control, tailings water management, industrial wastewater evaporation, environmental rehabilitation. |

| Deployment | Skid-mounted, modular design for rapid mobilisation; fully integrated electrical and pumping systems. |

| Operation | Continuous duty with ~50% average evaporation efficiency; scalable capacity with multiple units. |

| Safety & Monitoring | Automated control systems with remote telemetry to reduce operator exposure and optimise performance. |

6. Key Technical Data

| Specification | ZT-120 | ZT-100 | ZT-70 |

|---|---|---|---|

| Rated Power | 90 kW (120 HP) | 75 kW (100 HP) | 37.5 kW (50 HP) |

| Water Flow Capacity | 37.5 L/s (≈ 600 GPM) | 25 L/s (≈ 400 GPM) | 12.5 L/s (≈ 200 GPM) |

| Effective Evaporation Capacity | >1.5 million litres/day per unit (at ~50% efficiency) | Pro-rata | Pro-rata |

| Efficiency | ~50% average evaporation | ~50% | ~50% |

| Unit Type | Modular skid with integrated pump & MCC | Modular skid | Modular skid |

7. Performance Highlights

– High-throughput: Single units can evaporate over 1.5 million litres/day.

– Scalable: Multiple units can be configured for significantly larger capacities.

– Remote monitoring and automated control improve efficiency and reduce downtime.

– Optimised for challenging climates and variable site conditions.

8. Design & Construction Features

– Skid-mounted modular units for rapid site deployment.

– Integrated electrical MCCs, booster pumps, poly pipe and cabling included.

– Robust construction for harsh environments and continuous operation.

– Customisable configurations to suit site-specific water management challenges.

9. Operational Requirements

| Parameter | Requirement |

|---|---|

| Power Supply | Stable supply matching model kW rating (90/75/37.5 kW per unit). |

| Water Supply | Inflow ≥ unit flow capacity. |

| Site Conditions | Designed for variable climate; suitable for mining and industrial sites. |

| Maintenance | Periodic checks of pumps, electrical, and control systems. Remote monitoring aids proactive servicing. |

| Mobilisation Time | Typically 4–6 weeks for site deployment. |

10. Installation & Site Needs

– Minimal foundation (skid placement).

– Adequate footprint for units, pumps, and piping networks.

– Access to power infrastructure (voltage, switchgear).

– Poly pipe and booster pump installation for water inflow.

– Compliance with local environmental and regulatory frameworks.

11. Options & Configurations

– Hire, lease, or purchase models to reduce capital outlay.

– Multiple unit arrays for increased evaporation capacity.

– Advanced remote monitoring systems available.

12. Customer Data Required

To prepare a full proposal, ARC Vanture JV requires:

1. Expected water volumes (litres/day).

2. Inflow rates (normal and peak).

3. Desired evaporation capacity.

4. Site power supply details.

5. Site layout and space availability.

6. Climate and environmental conditions.

7. Compliance / permitting requirements.

8. Target mobilisation timeframe.

13. Warranty & Support

– Full service from design to commissioning.

– Ongoing monitoring, maintenance, and technical support.

– Flexible financing, hire, or lease packages available.